This past November, LHB’s CEO Rick Carter and Design Technology Manager Dan Stine (that's me) had the opportunity to tour the Vancouver House in Vancouver, British Columbia, Canada. The project was designed by Bjarke Ingels Group (BIG) from Denmark; click here to learn more about this project on their website.

I wrote a blog post about this amazing project tour for the LHB Blog. And our equally amazing tour guide provided a write-up on the project and the HVAC system his company designed for the project.

In today's post I will tell you about the ironic twists leading up to this project tour, provide an overview of the HVAC system written by our tour guide, and provide the link to the LHB blog post.

Keep reading to learn more...

While visiting his son Eric, who lives in Squamish, which is just north of Vancouver, during the [US] Thanksgiving break, Rick was able to schedule a tour of the Vancouver House. How this opportunity came about has a twist of irony to it… LHB had hosted a presentation in its Minneapolis office and Cyrus Kangarloo, North American Operations Manager at Jaga Canada Climate Systems, was one of the presenters and talked about the Vancouver House project. When Rick mentioned his upcoming trip to Canada, Cyrus offered to give a tour. In working out the details, it turns out Cyrus is good friends and ski buddy with Rick’s son Eric!

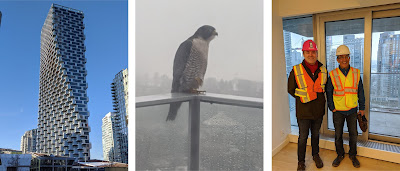

Dan was also visiting the area to tour the Vancouver Film School where his daughter will be attending in early 2020. In yet another twist of irony, in a metropolitan area of 2.5 million people Rick and Dan crossed paths at a restaurant; see photo below of Dan (left) and Rick (right)! This chance encounter prompted Rick to invite Dan on the tour.

Here is a link to the LHB blog post on this project:

Our tour guides were:

Here are a few photo samples from the article (click to enlarge). The building is super interesting; it's floor area nearly doubles at the top, and - yes - that is a real falcon siting outside on the railing...

The reminder of this post is about the design and installation of the suite level heating/cooling system and some history on the project by Cyrus Kangarloo. This is also linked from the LHB article, but since he wrote this per my request, I wanted to give this great write-up maximum exposure:)

The mechanical consultant on the project (Integral Group) was really scratching their heads about how to heat and cool the space without any ceiling drops or ductwork available and fortunately for Jaga, we had a potential solution for them. It took 9 prototypes, lots of meetings with all parties (structural engineers, mechanical consultant, GC, controls and of course the mechanical contractor) to come up with the final solution. Challenges here were convincing the mechanical contractor to have pre-insulated PEX pipe laid in the slab, how to slope the condensate pipe, what the finished casing would look like, how the system would be controlled, what would happen with the window/balcony transition.

The initial concept was to have a Jaga Clima-canal placed within the concrete slab, embedded 4” at the perimeter. This had been done before on many projects in Europe but never on a high rise in Vancouver. The structural engineer would not let that fly, especially on a twisty structure like Vancouver House. In the end, it was determined that a unit standing 7.9” on top of the floor would act as a step while handling the heating/cooling demands. High performance glazing and exterior overhangs were employed to ensure the cooling load was not massive and the Jaga Clima-canals could accommodate the hottest of days.

Initial concept was 4” deep Clima-canal in the slab:

Structural did not allow for embeds at the perimeter as Vancouver is a seismically active zone. The next concept was on top of the slab but dealing with condensate here was a challenge:

Initial mockup, Coke can for scale:

BIG didn’t go for the Ski Chalet look:

In the end it was decided that we would raise the Clima-canal up on 3.5” tall pedestals and make the unit slightly wider to allow for a condensate pipe to be sloped underneath. This led to the following.

Final prototype exploded drawings showing finished front fascia and trim pieces (note the electrical outlet joiner trims):

Final prototype in the factory in Belgium:

Condensate pipe routed underneath:

Jaga’s director Jan Kriekels approved of the final product:

Having all the heating/cooling mounted at the floor at the perimeter meant they could have 8’ tall floor to ceiling height and offer A/C. Ensured the structure could maximize the number of floors available:

Picture of the chandelier just because:

For BIM Chapters updates, follow @DanStine_MN on Twitter or connect on LinkedIn

Check out my video-based courses on ArchSmarter.

I also write blog posts for Enscape - a new paradigm in rendering, animation and VR for AEC.

I wrote a blog post about this amazing project tour for the LHB Blog. And our equally amazing tour guide provided a write-up on the project and the HVAC system his company designed for the project.

In today's post I will tell you about the ironic twists leading up to this project tour, provide an overview of the HVAC system written by our tour guide, and provide the link to the LHB blog post.

Keep reading to learn more...

While visiting his son Eric, who lives in Squamish, which is just north of Vancouver, during the [US] Thanksgiving break, Rick was able to schedule a tour of the Vancouver House. How this opportunity came about has a twist of irony to it… LHB had hosted a presentation in its Minneapolis office and Cyrus Kangarloo, North American Operations Manager at Jaga Canada Climate Systems, was one of the presenters and talked about the Vancouver House project. When Rick mentioned his upcoming trip to Canada, Cyrus offered to give a tour. In working out the details, it turns out Cyrus is good friends and ski buddy with Rick’s son Eric!

Dan was also visiting the area to tour the Vancouver Film School where his daughter will be attending in early 2020. In yet another twist of irony, in a metropolitan area of 2.5 million people Rick and Dan crossed paths at a restaurant; see photo below of Dan (left) and Rick (right)! This chance encounter prompted Rick to invite Dan on the tour.

|

| Chance encounter in Vancouver |

Here is a link to the LHB blog post on this project:

VISUALLY INSPIRED IN VANCOUVER

Our tour guides were:

- Cyrus Kangarloo P. Eng, North American Operations Manager, Jaga Canada Climate Systems

- Chris Heerius, Executive Director and Climate Designer, Jaga Canada Climate Systems

- Simranjit Brar, B. Tech., PMP, Assistant Project Manager, Icon West Construction

Here are a few photo samples from the article (click to enlarge). The building is super interesting; it's floor area nearly doubles at the top, and - yes - that is a real falcon siting outside on the railing...

The reminder of this post is about the design and installation of the suite level heating/cooling system and some history on the project by Cyrus Kangarloo. This is also linked from the LHB article, but since he wrote this per my request, I wanted to give this great write-up maximum exposure:)

Project History and HVAC design Overview

The developer (Westbank) first approached Jaga about how to come up with a space saving heating/cooling design in 2011 for a project called 1400 Howe. Back then, we got some swanky Bjarke Inges Group renderings of pink polygons twisted into different shapes for what the building would look like. We were all really excited to see something like this being conceptualized in Vancouver. The City of Vancouver has a view cone height restriction on all buildings in downtown and as such the tower had to be limited to a specific height. The developer wanted to ensure they had the most number of floors available to them and really limited the floor to ceiling heights of the suites. This meant there was almost no chance to place any overhead ductwork in the space (i.e. VRF and overhead fan coils were not an option).The mechanical consultant on the project (Integral Group) was really scratching their heads about how to heat and cool the space without any ceiling drops or ductwork available and fortunately for Jaga, we had a potential solution for them. It took 9 prototypes, lots of meetings with all parties (structural engineers, mechanical consultant, GC, controls and of course the mechanical contractor) to come up with the final solution. Challenges here were convincing the mechanical contractor to have pre-insulated PEX pipe laid in the slab, how to slope the condensate pipe, what the finished casing would look like, how the system would be controlled, what would happen with the window/balcony transition.

The initial concept was to have a Jaga Clima-canal placed within the concrete slab, embedded 4” at the perimeter. This had been done before on many projects in Europe but never on a high rise in Vancouver. The structural engineer would not let that fly, especially on a twisty structure like Vancouver House. In the end, it was determined that a unit standing 7.9” on top of the floor would act as a step while handling the heating/cooling demands. High performance glazing and exterior overhangs were employed to ensure the cooling load was not massive and the Jaga Clima-canals could accommodate the hottest of days.

Initial concept was 4” deep Clima-canal in the slab:

Structural did not allow for embeds at the perimeter as Vancouver is a seismically active zone. The next concept was on top of the slab but dealing with condensate here was a challenge:

Initial mockup, Coke can for scale:

BIG didn’t go for the Ski Chalet look:

In the end it was decided that we would raise the Clima-canal up on 3.5” tall pedestals and make the unit slightly wider to allow for a condensate pipe to be sloped underneath. This led to the following.

Final prototype exploded drawings showing finished front fascia and trim pieces (note the electrical outlet joiner trims):

Final prototype in the factory in Belgium:

Condensate pipe routed underneath:

Jaga’s director Jan Kriekels approved of the final product:

Having all the heating/cooling mounted at the floor at the perimeter meant they could have 8’ tall floor to ceiling height and offer A/C. Ensured the structure could maximize the number of floors available:

Picture of the chandelier just because:

For BIM Chapters updates, follow @DanStine_MN on Twitter or connect on LinkedIn

Check out my video-based courses on ArchSmarter.

I also write blog posts for Enscape - a new paradigm in rendering, animation and VR for AEC.